NDTL Develops CO₂ Component Test Capability and Successfully Tests High Efficiency Transcritical CO₂ Compressor

NDTL Propulsion and Power (NDTL) has designed and built a closed test loop and a CO₂ storage and management system to support testing for supercritical and transcritical CO₂ power and thermal management components. The test loop can be installed in NDTL’s 10-megawatt, 5-megawatt, or 3-megawatt test cells to match the power, speed, and flow requirements of a particular test article. NDTL recently completed testing of the first stage of a high-efficiency multistage transcritical CO₂ compressor.

The development of high-efficiency compression systems is important for the design of CO₂-based power and heat pump cycles. Axial compressors inherently have higher efficiency compared to centrifugal and reciprocating machines, but they have not yet been tested or demonstrated using CO₂ as the working fluid. The high fluid density, high power density, and significant real gas effects present technical challenges in designing and testing an axial compressor.

With support from the U.S. Department of Energy (DOE), the team composed of NDTL, Echogen, and the University of Cincinnati is demonstrating the system efficiency advantages of utilizing axial compressors in renewable energy storage systems. This is being accomplished with the design and test of a 3-stage transcritical CO₂ axial compressor.

NDTL designed and fabricated the test loop, performed the mechanical design of the high-power density compressor, and is executing the test program. The University of Cincinnati, employing best practices from air-breathing compressors for aero-propulsion engines, performed the aerodynamic compressor design. Echogen leads the overall program and developed the transition path to a fielded system. Echogen has also provided its expertise in supercritical CO₂ systems.

The test loop consists of a variable speed drive motor, CO₂ inventory system, a heat exchanger between the CO₂ loop and the water/glycol loop, high accuracy Coriolis flowmeter, and cooling towers. The closed loop is installed in a test cell fully equipped with data acquisition and control systems.

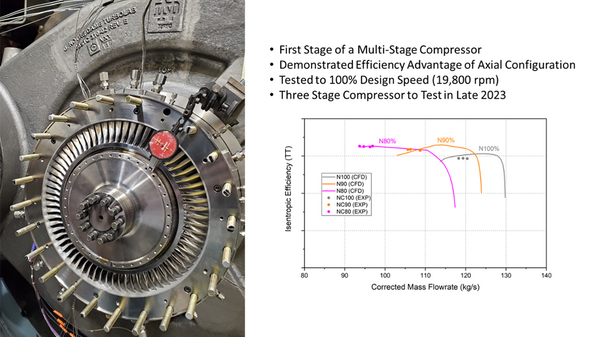

The initial testing of the first stage of the 3-stage axial compressor was completed at NDTL using the closed sCO₂ compressor test loop installed in the 10 MW cell. Steady-state conditions were obtained by removing enthalpy from the loop using a CO₂ – water/glycol heat exchanger. The nominal design speed, pressure ratio, and mass flow rate of the compressor are 19,800 rpm, 1.42, and 125 kg/s, respectively.

The compressor mapping test was performed from 60% to 100% corrected speed. The pressure ratio and the efficiency of the compressor were measured through the total pressure and total temperature rakes, which were installed at the inlet and the exit of the test compressor. All nine rakes were calibrated via an in-house flow calibration jet facility. The measured pressure ratio and the efficiency of the compressor aligned well with design predictions, and the measured isentropic efficiency of the compressor was above 90%.

NDTL is preparing to begin testing of the 3-stage compressor. Updates are forthcoming.

Originally published by at ndtl.nd.edu on November 27, 2023.

Latest Research

- ‘A special challenge’: German studies scholar wins National Humanities Center fellowship for research on medieval womenFor CJ Jones, the joy of research is not the answers but the journey. And the next step on that journey is a fellowship with the National Humanities Center. …

- Notre Dame Lead Innovation Team partners with local WIC program to identify, prevent lead poisoning in childrenB.A.B.E. store “shoppers” now have something new to help their families: free lead screening kits offered by the University of Notre Dame’s Lead Innovation Team.

- Notre Dame Welcomes Ninth Cohort of Warrior-Scholars for Transformative Academic JourneyNOTRE DAME, IN – The University of Notre Dame recently concluded its ninth successful Warrior-Scholar Project (WSP) boot camp, hosting 34 dedicated Warrior-Scholars from June 21st to 28th. This intensive, week-long academic residency provided transitioning service members and veterans…

- Entrepreneurship and Empowerment in South Africa study abroad program celebrates 25 yearsThis year, the Entrepreneurship and Empowerment in South Africa (EESA) program marked its 25th year of operation. EESA is a six-week summer study abroad program that enables students to help historically…

- Vatican honors Martin and Carmel Naughton with papal awardCarmel…

- Brain tumor growth patterns may help inform patient care managementAssistant Professor Meenal Datta (University of Notre Dame/Wes Evard) A team of researchers from the University of Notre Dame, Harvard Medical School/Massachusetts General Hospital, and Boston University has developed a technique for measuring a brain tumor’s mechanical force and a new model to estimate how much brain tissue a patient has lost.